For someone putting together their first piece of self-assembly furniture, a missing screw could cause a lot of frustration. Also, the assembly instructions in those early years were not always that easy to understand – IKEA had not yet perfected the fine art of explaining a complex process in a simple way.

Going nuts

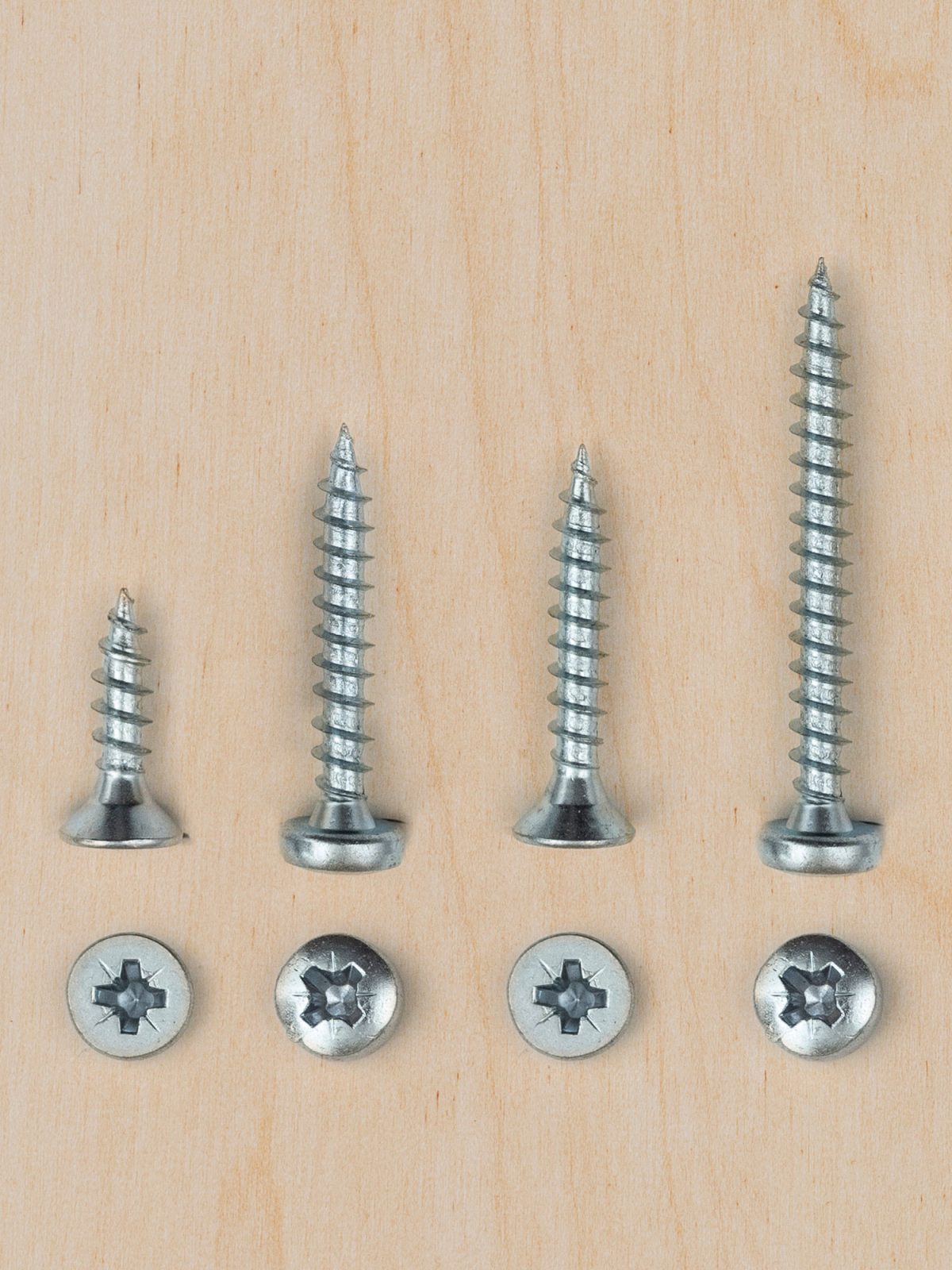

No screws loose

The legend of the missing screw in IKEA flatpacks has existed since the 1960s, when IKEA began expanding dramatically. The logistics were not always up to scratch on the packaging lines, and sometimes an important component was missing from the little bag of screws, nuts and Allen key.

Many IKEA veterans feel that from the 1970s, there was rarely anything missing from the flatpacks. On the contrary, there was sometimes an extra screw or nut in the hardware pack. One of these veterans is Thomas Blomqvist, who began his long career with IKEA as store manager in Kållered, Gothenburg in 1972. “Having too many screws could also be frustrating for customers,” he says today. “There you were with a newly assembled BILLY bookcase but with one screw left over, wondering where you’d gone wrong and if it all might fall apart.”

To deal with the problem of surplus nuts and screws, tougher demands were placed on suppliers and internal procedures, which led to a gradual improvement. One important step was the ‘module factory’ at IKEA, where they had to weigh every single hardware pack before it went into the flatpack. “We knew exactly what a set of hardware for each product should weigh, so if it was lighter or heavier it was set aside and dealt with,” Thomas explains.

A hard nut to crack in other countries

There was a toolbox in virtually every home in Sweden during the second half of the 20th century. As an old farming society, there was a strong tradition of Do-It-Yourself, and most people – both men and women – could hammer in a nail and work with an Allen key. But in many other countries where IKEA established new stores in the 1970s, DIY was a brand new concept, especially in towns and cities. A lot of people did not know how to use tools or follow assembly instructions.

“The myth of components missing from the flatpack became something people could blame.”

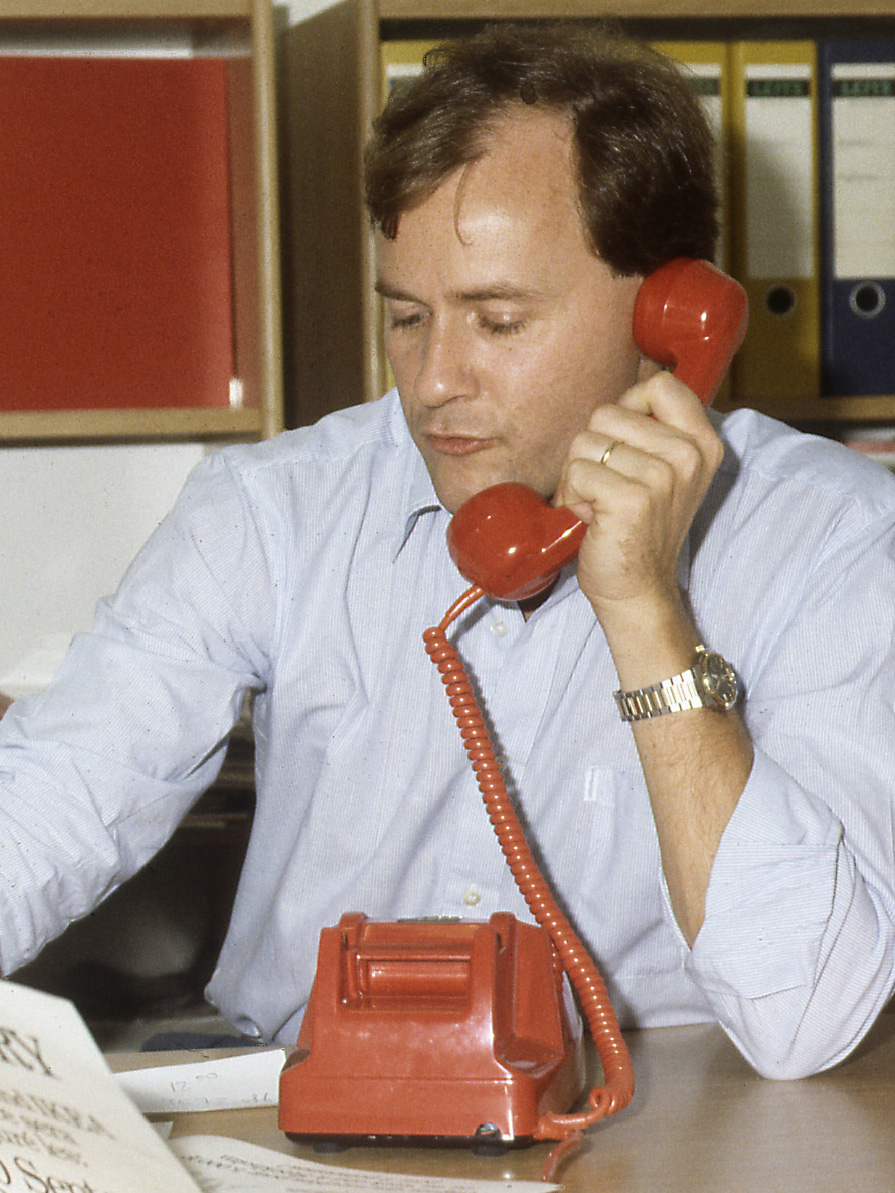

“There were also a lot of ‘handy’ men who didn’t even bother to read the assembly instructions, and the results were rarely good. The myth of components missing from the flatpack became something people could blame,” says Thomas Blomqvist with a laugh. But he also admits that the instructions were far too hard to understand in those days.

To help improve the instructions, in the 1980s IKEA worked with focus groups in different countries. Jan Kjellman, head of IKEA in the US back then, explains: “We invited a few people along, gave them flatpacks, and then filmed them as they started dealing with the instructions and contents,” Jan remembers.

Getting better every day

These focus groups helped IKEA realise it had to start doing things better, and since the 1980s IKEA has worked consciously to make it easier for customers to put their furniture together without going nuts. “Nowadays, there are professional communicators doing this work. They have to explain what to do using no words at all, and make sure it can be understood anywhere in the world,” says Jan Kjellman.

In addition, visual communication without text also saves paper – a big plus for the environment. And of course, the assembly instructions are also readily available online.

The IKEA Do-It-Yourself concept is known around the world, and people are no longer surprised at having to put together their own flatpack furniture. And a finely tuned system behind the scenes guarantees that all the bits are there. Of course, the occasional nut or screw might roll away and disappear during assembly, but new ones can always be ordered online or collected free from any IKEA store.